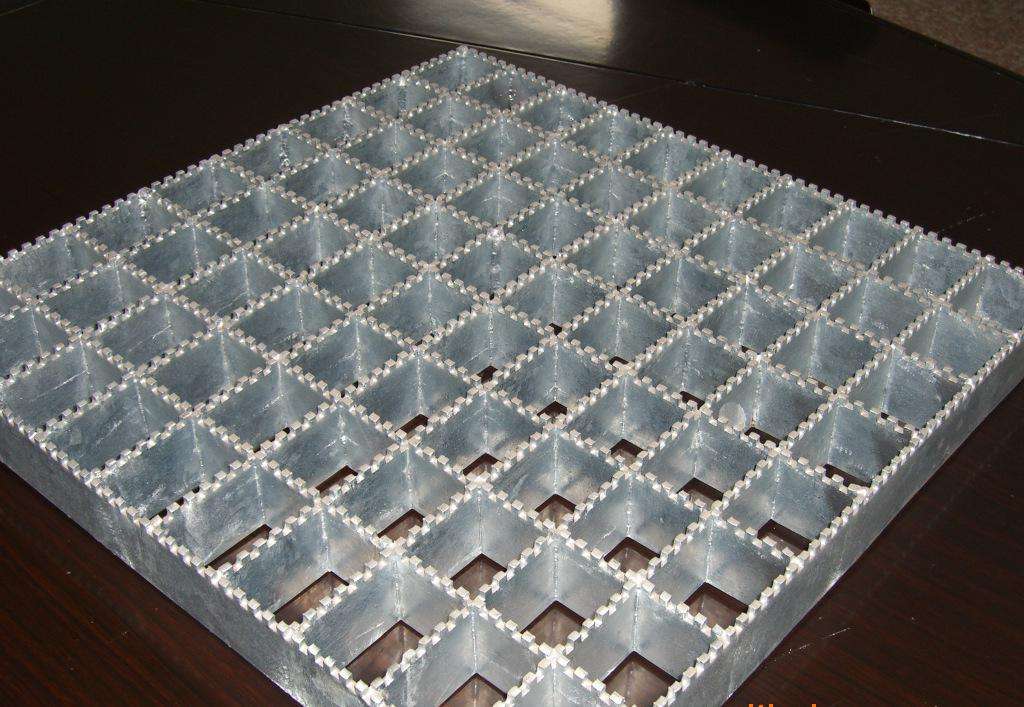

Hot dip galvanized steel grating is made of low carbon steel flat plate and twisted square steel in the welding machine horizontal and vertical welding into a grid grid plate, after the hot dip galvanized process it has super corrosion resistance and impact resistance, it uses a strong grid welding structure so as to have a very good bearing capacity.

The structure is very light and beautiful appearance of the atmosphere, is a durable product and also has a certain anti fouling function, hot dip galvanized steel grid chemical and physical characteristics are very stable, not easily by air and microbial corrosion and oxidation, is a steel grid application performance is very good.

It is also known as hot dip galvanized steel grid platform, this platform steel grid plate is widely used in the industrial field of steel grid products, platform steel grid plate has a strong resistance to the impact of the surface, is a new type of building supplies is being updated. Can increase the surrounding weld guard board, also can install fittings and other accessories, can also be in need of often through or mobile platform steel grid plate installed on the handle and hinge, the platform of the specifications of the steel plate are diverse, generally classified according to the spacing of flat steel, steel case board this platform is one of the most resistant force of steel plate is also the most economical and portable products, There are also some platform steel grids used specifically for mining.

There is also a geometric shape and shape is not the same special-shaped steel grid products, this special steel grid is based on the different needs of different customers and different design produced steel grid. The use of special steel grid can effectively speed up the progress and efficiency of construction so as to avoid the secondary cutting of the project.

This special steel lattice welding spot is very strong, has a very high stability and integrity, is a very good strength of steel lattice products, so this special steel lattice has a very good bearing capacity and durability, is widely used in all walks of life in a very good performance of steel lattice products.

Plug-in steel grid is made of high quality low carbon flat steel or other metal materials by welding precision mechanical equipment. Because of the excellent welding process, its shape is very beautiful and delicate, with quite good beauty and integrity, and the load capacity of this inserted steel lattice is also very good, with a very good service life, is a very unique structure of a steel lattice.

Inserted steel lattice is mainly used for heat dissipation and ventilation of precision products, inserted steel lattice can also be used for filtration and dustproof and other functional components products, the opening rate of inserted steel lattice is the main factor that determines the precision of the product, the higher the opening rate of inserted steel lattice is, the higher the precision requirement of the relative hole of inserted steel lattice will be. The main problem of inserting steel grid is the phenomenon of plugging holes, which is mainly because the construction process of inserting steel grid is not completed in the dust-free workshop. The precision of steel lattice plate is very high, the surface of steel lattice plate is smooth and uniform without hair, the quality of steel lattice plate is very good, and the reputation is good.

Post time: Jun-09-2022