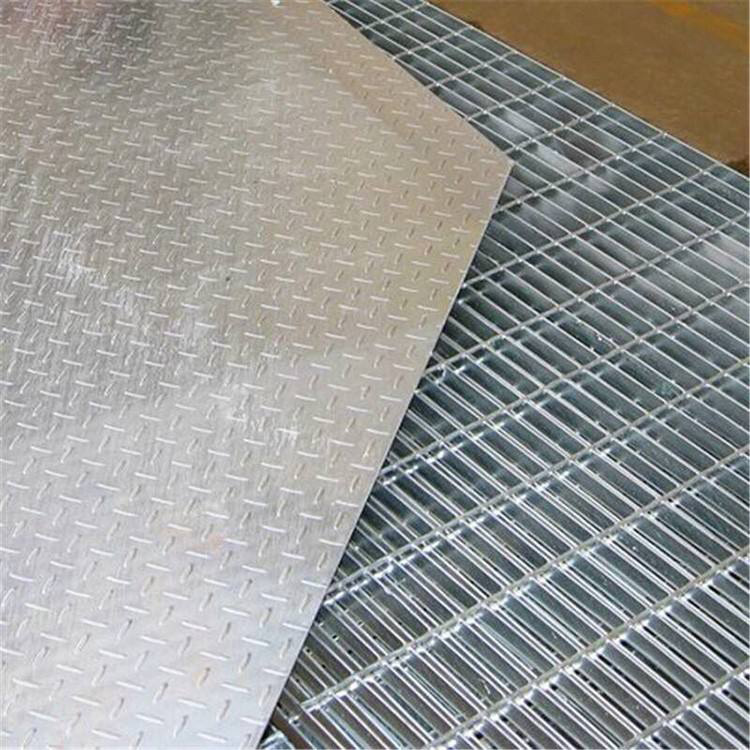

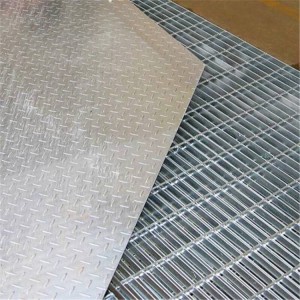

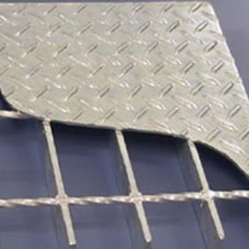

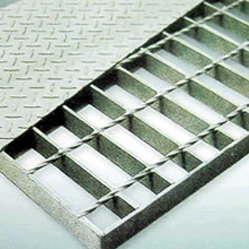

Compound type steel bar grating

Product description

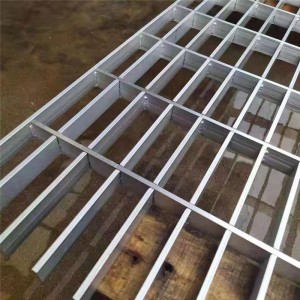

Compound steel grating consists of steel grating plate with certain loading ability and surface seal retreader. After hot dip galvanized treatment, the compound steel grating plate will warp and distort. The compound steel grating plate commonly takes series 3 steel grating plate as basic plate, also can use series 1 or series 2 steel grating plate. Retreader usually uses 3mm plate, also can uses 4mm, 5mm and 6mm plate.

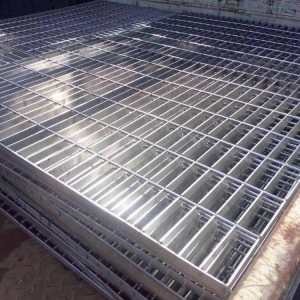

Compound steel gratings are widely used in most general industrial plants as well as commercial buildings, it has wide applications as walkways, platforms, safety barriers, drainage covers and ventilation grates. It is also ideal for use as mezzanine decking since it supports the same loads as comparable solid flooring. More than that, its cost saving openness maximizes the circulation of air, light, heat, water and sound, while promoting cleanliness.

Materials: carbon steel and stainless steel

finish

* Galvanized

* Powder coated

* Slip resistant finishes

advantage

★ Economical

★ Durable

★ High strength-to-weight ratio

★ Versatile

★ Low maintenance Surfaces

★ Serrated (slip resistant)

Application

Compound steel grating is widely used in the platform, corridor, bridge, well covers and stairs, fencing for petroleum, chemical, power plant, waste treatment plant, civil engineering projects and environmental projects. Because of its robust design and spanning abilities, this kind of grating is extremely strong and safe for the supportive structures on decking's, mezzanine floors and elevated walkways.

Installation Method

★ Directly weld the steel grating plate or footboard in the support steel structure, and the welding place brushes zinc powder paint.

★ Uses special-purpose steel grating installment clamp, which does not destroy galvanization level, disassembles and assembles conveniently. Each set of installation clamp includs up-clamp, down-clamp, head bolt and nut.

★ According to the need, provide stainless steel installment clamp or bold jointing and so on tight method.

★ Generally the gap between steel grating plate is 100mm.

★ The steel grating plate which approaches the vibration should weld or add rubber packing.

Special specifications can be produced by the customer's requirements.