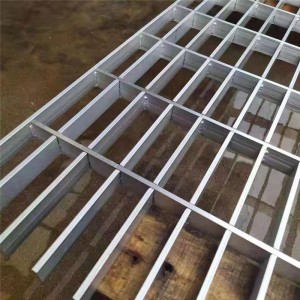

Heavy duty type steel bar grating

Product description

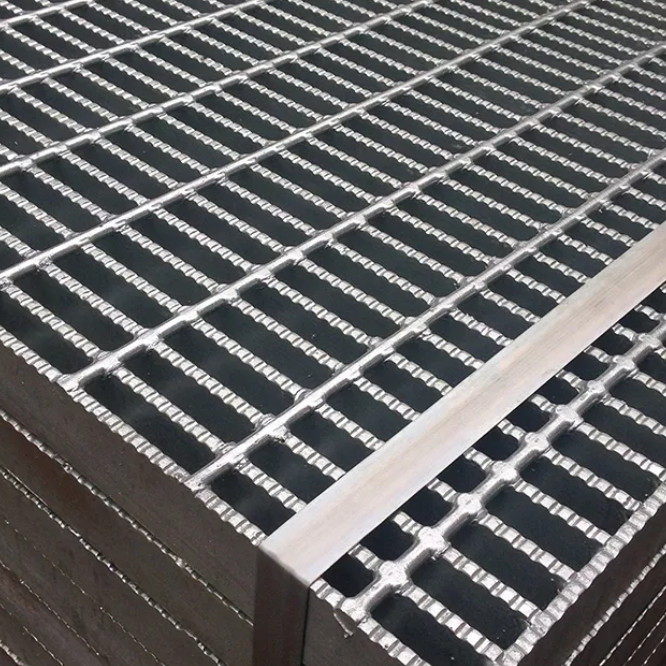

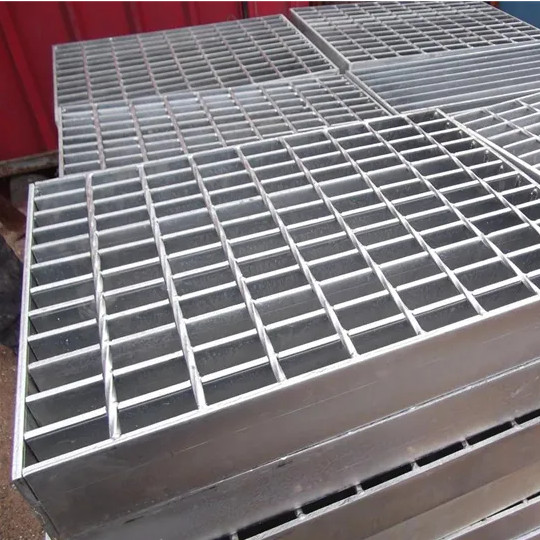

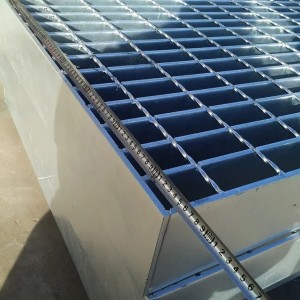

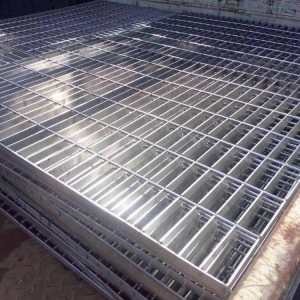

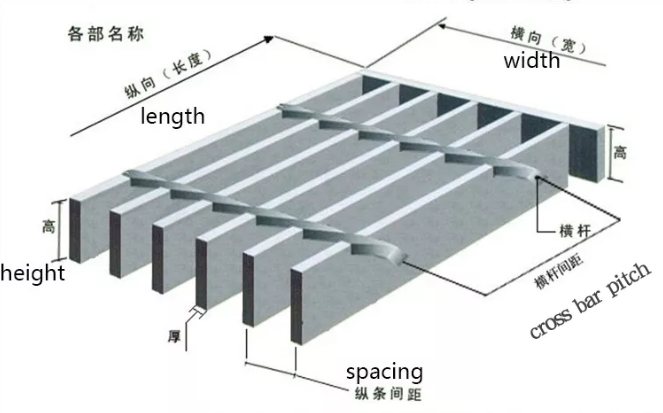

Steel Grating made by welding with flat or serrated steel and cross/round bars with certain distances. Our Galvanized Steel Grating enjoy the feature of high strength, light structure, high bearing, convenience for loading and other properties. The hot dipped zinc coating gives the product excellent anti-corrosion.

1)Raw material :Low carbon steel, stainless steel, aluminum alloy

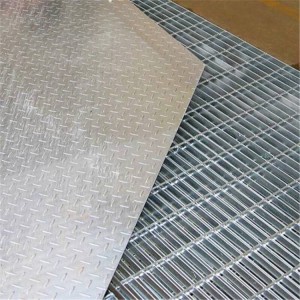

2)Types of Steel Grating:Plain/smooth type, I type ,Serrated/teeth type.

3)Open-end type and closed-end type

Heavy-duty welded steel grating is manufactured by fusing bearing bars and cross bars together at high temperatures to form a permanent joint. This type of grating utilizes deeper and thicker bearing bars to provide greater durability, strength and rigidity than light-duty grating options. Available material types include economical carbon steel and corrosion-resistant stainless steel.

Designed to carry heavy rolling loads and maintain the same level of performance over many years of use, heavy-duty welded steel grating is ideal for a variety of applications. Common uses include airfield landing mats, highway bridge decking, ventilation grills, curb inlet grates, ramps, docks, sidewalks, concrete reinforcements, vault covers, industrial flooring, trenches, marine platforms and paper mills.

Why is it called Heavy-duty steel grating? Because it has very strong bearing capacity.The bearing bar to produce the heavy-duty steel grating has very thick thickness,such as 5mm,8mm,10mm,and the height of the bearing is very high,such as 10mm,15mm,20mm.After these strong bearing bar welded together,the steel bar grating will have very strong bearing capacity.It is ok when the trucks carried tons of goods go through above the steel grating.

Specification

|

Specification of Steel Grating |

|

| Remarks: Special Material, High Zinc Coating and New Style can be Customized. | |

|

Material Standard |

ASTM A36, A1011, A569, Q235, S275JR, Stainless steel 304/316,

Mild steel & Low carbon steel, etc |

|

Bearing Bar (Width x Thickness) |

25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10…..100 x10mm etc;

I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1''x3/16'', 1 1/4''x3/16'', 1 1/2''x3/16'', 1''x1/4'',1 1/4''x1/4'', 1 1/2''x1/4'', 1''x1/8'', 1 1/4''x1/8'', 1 1/2''x1/8'' etc |

|

Bearing Bar Pitch |

12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3,32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc.

US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

|

Twisted Cross Bar Pitch |

38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

|

Surface Treatment |

Untreated(black), Hot-dipped galvanized, Powder coated, Electroplate, Painting or as per customers' requirement. |

|

Grating Style |

Plain / Smooth, Serrated / Teeth, I bar, Serrated I bar |

|

Packing |

(1) Bandage and Paperboard: Generally applies to neat steel plate;

(2) Screw Locking Method: Use 4 screw rods through the aperture of the steel grid, for high strength; (3) Steel Pallet: Traditional export packing. |

|

Payment Terms |

T/T, L/C, Western Union |